XPS Extrusion Insulation Board Production line (CO2 foaming technology)

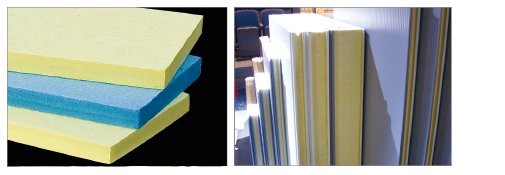

Widely used in roof thermal insulation system; Thermal insulation inside and outside the walls of cold storage, barracks, grain storage and civil construction; Airport runway, square and other ground construction; Civil engineering of roads and railways; Apartments, office buildings, factories and other buildings in the partition system and so on

Product characteristics

Has a perfect obturator honeycomb structure, is currently recognized as the market insulation material. It is made of recycled EPS polystyrene board granulation material as the main raw material by die head extrusion foaming, shaping, traction, cutting to complete the production process, its density, water absorption, thermal conductivity and steam permeability coefficient are lower than other types of plate insulation materials, so it has good strength, light weight, air permeability, corrosion resistance, anti-aging, low price characteristics, Widely used in roof thermal insulation system; Thermal insulation inside and outside the walls of cold storage, barracks, grain storage and civil construction; Airport runway, square and other ground construction; Civil engineering of roads and railways; Apartments, office buildings, factories and other buildings in the partition system and so on.

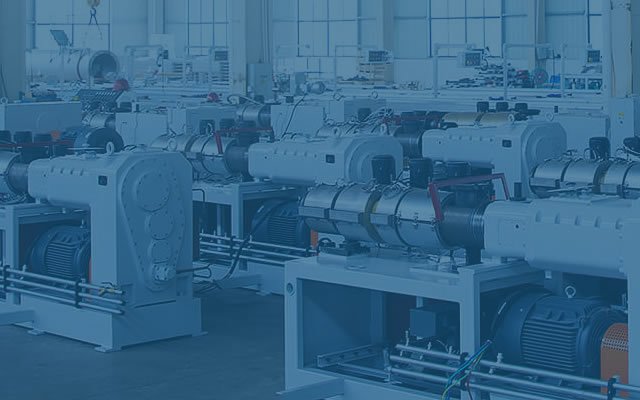

XPS equipment has two kinds of single screw series extruder and parallel parallel double series single screw extruder, specifications are: Ø135/Ø150 single screw extruder series and Ø75/Ø150 parallel parallel double series single screw extruder. Because of the excellent mixing efficiency, the same direction twin screw extruder can process the ingredients composed of many components.

The newly developed CO2 foaming unit of Jwell Company uses CO2 instead of freon and butane to produce XPS extruded plate with green, low cost.