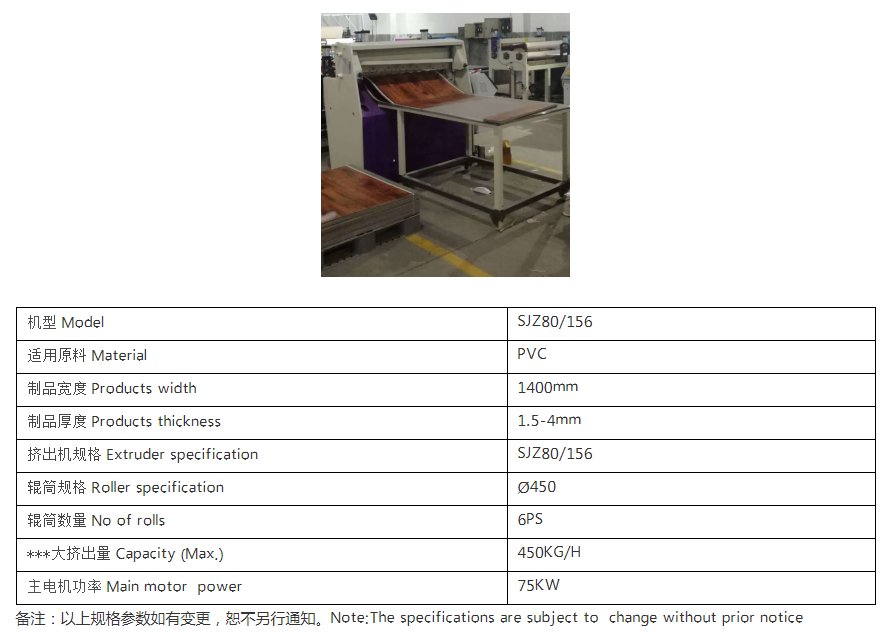

LVT soft composite flooring production line

Traditional steam press composite LVT floor production line, due to the need to use boiler heating to generate steam for a long time of molding, not only energy consumption, but also need a large number of personnel operation, resulting in low production efficiency, at the same time, the machine occupies a large space, complicated operation. The new composite structure LVT soft composite floor production line is developed through a series of technical difficulties, the production line fills the gap in the domestic market, can completely replace the traditional steam molding composite process.

Product characteristics

Traditional steam press composite LVT floor production line, due to the need to use boiler heating to generate steam for a long time of molding, not only energy consumption, but also need a large number of personnel operation, resulting in low production efficiency, at the same time, the machine occupies a large space, complicated operation.

The new composite structure LVT soft composite floor production line is developed through a series of technical difficulties, the production line fills the gap in the domestic market, can completely replace the traditional steam molding composite process.

The production line has the following advantages:

1. Occupied site

2, easy to operate

3, high production efficiency

4, replace the product fast, can be switched between any color

5, low production cost