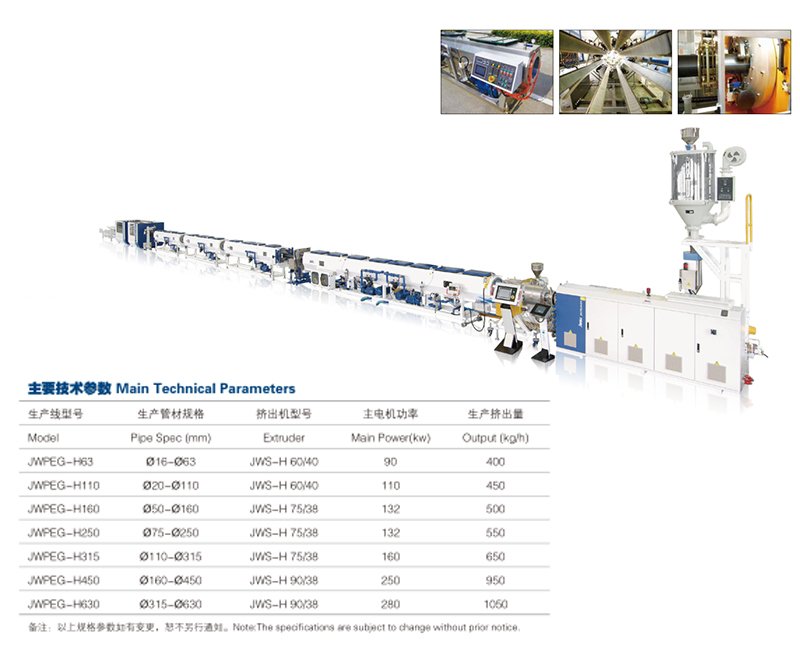

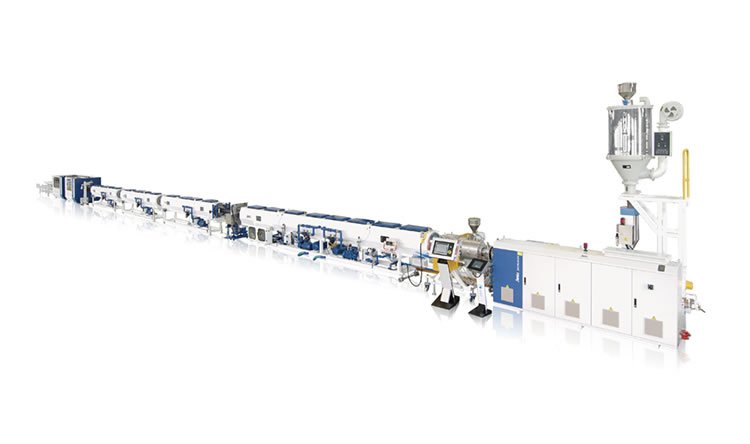

High - speed and energy - saving HDPE solid - wall tube extrusion line

Our newly developed energy-saving high speed production line is suitable for high speed extrusion of polyolefin pipes. Energy saving 35%, production efficiency doubled. 38-40D length-diameter ratio, specially designed screw structure and feeding tank barrel, make melt extrusion and plasticizing effect are greatly improved. With high torque and high strength gear box, the equipment runs stably.

Product characteristics

The energy-saving high-speed production line newly developed by our company is suitable for high-speed extrusion of polyolefin pipes. Energy saving 35%, production efficiency doubled. The specially designed screw structure and feeding tank barrel make melt extrusion and plasticizing effect greatly improved. With high torque and high strength gear box, the equipment runs stably.

Extrusion die head and sizing sleeve adopt advanced design structure, with PLC frequency conversion controlled vacuum cooling box, servo driven multi-track tractor, high-speed non-chip cutting machine, coupled with accurate pipe meter weight control system, the production line operation is highly reliable, energy-saving, efficient, low noise, is the current model of high performance pipe extrusion equipment.