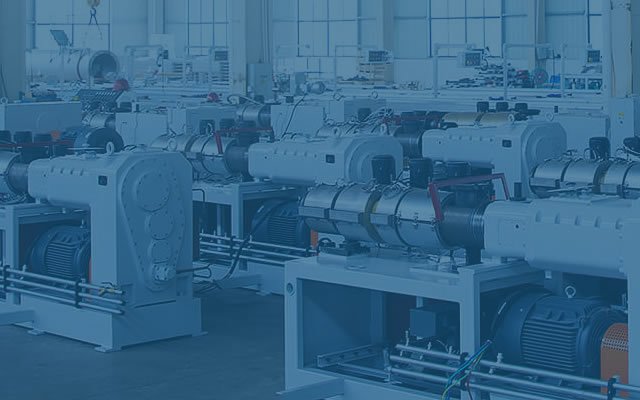

Three-layer PVC solid wall pipe co-extrusion line

Performance advantage: More than 2 SJZ series conical double hosts are used for co-extrusion production of three-layer PVC pipe. The sandwich layer of the pipe is high calcium PVC or PVC foam raw material.

Product characteristics

Performance advantage: More than 2 SJZ series conical double hosts are used for co-extrusion production of three-layer PVC pipe. The sandwich layer of the pipe is high calcium PVC or PVC foam raw material.

1. The main machine adopts super wear-resistant alloy screw barrel; Double screw feeder feeding uniform, no bridge powder;

2, the optimized design of the PVC three-layer mold, the runner after chrome plating high polishing treatment, wear resistance and corrosion resistance; Matching sizing sleeve, fast production speed, good pipe quality;

3, the cutting machine adopts rotary clamping device, adapt to different pipe diameters, avoid the trouble of frequent replacement fixture. Equipped with new adjustable floating chamfering mechanism, according to the size of pipe diameter and wall

Thickness adjustment chamfer size, cut off, chamfer step molding. Closed suction device, dust absorption effect is better.