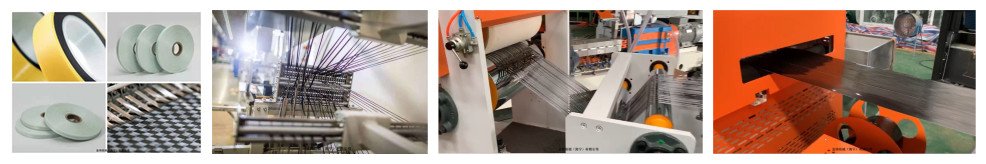

PA nylon continuous carbon fiber prepreg belt production line

Continuous carbon fiber reinforced PA unidirectional prepreg tape is not sticky on the surface, so it must be laminated using a double tape composite press (belt or steel machine depending on the material). First, the PA unidirectional prepreg strip is manually placed and then laminates according to the desired thickness to form the PA unidirectional prepreg strip laminate. Laminating treatment temperature between 230℃***270℃.

Product characteristics

Nylon (PA) + continuous carbon fiber reinforced thermoplastic unidirectional prepreg belt was produced by thermoplastic extrusion melt impregnation method.

1, the type of fiber used: carbon fiber or glass fiber;

2, the use of extruder model: single screw extruder or twin screw extruder;

3, PA: carbon fiber = 50% : 50%;

4, plastic raw materials can be used: PA/PP/PE;

5, production product thickness: 0.2-0.25 mm;

6, production width: 360mm / 635mm;

Continuous carbon fiber reinforced PA unidirectional prepreg tape is not sticky on the surface, so it must be laminated using a double tape composite press (belt or steel machine depending on the material). First, the PA unidirectional prepreg strip is manually placed and then laminates according to the desired thickness to form the PA unidirectional prepreg strip laminate. Laminating treatment temperature between 230℃***270℃.

The advantages and disadvantages of continuous carbon fiber reinforced PA prepreg will directly affect the performance of unidirectional prepreg strip laminates. Continuous carbon fiber reinforced PA prepreg has high tensile strength to ensure the strength of unidirectional prepreg strip laminates.