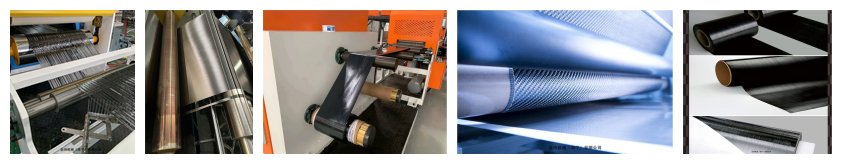

PEEK Continuous carbon Fiber reinforced prepreg Belt production line

PEEK, as a representative of high-performance thermoplastic polymer, has fracture toughness up to 2.0 KJ/m, 20 times that of epoxy resin.

Product characteristics

Advantages of continuous carbon fiber CF/PEEK Composite:

1. Good fracture elongation and fracture toughness PEEK, as a representative of high-performance thermoplastic polymer, has fracture toughness up to 2.0 KJ/m, 20 times that of epoxy resin.

2. Excellent delamination resistance and fatigue resistance PEEK has good impact resistance, which is a kind of heat resistant resin with better impact resistance. Meanwhile, PEEK has high rigidity, good dimensional stability, small linear expansion coefficient, and excellent long-term creep resistance and fatigue resistance characteristics.

3, excellent chemical corrosion resistance PEEK has excellent chemical corrosion resistance to acid, alkali and almost all organic solvents have strong corrosion resistance, only at high temperature by halogen and strong acid corrosion, at room temperature only dissolved in concentrated sulfuric acid.

4, excellent moisture and heat resistance PEEK has low moisture absorption rate, good moisture and heat resistance, and can still maintain good mechanical properties under high temperature and humidity. In addition, it has outstanding hydrolysis resistance, low moisture absorption and permeability, and steam, water and seawater resistance.

5, excellent sliding wear and fretting wear PEEK can maintain high wear resistance and low friction factor at 250 ℃.

6, Biocompatibility Studies have shown that short carbon fiber reinforced PEEK as a prosthesis material implanted in animals, its cytotoxicity is low, in line with the cytotoxicity indexes of medical implant materials, has good blood compatibility and histocompatibility.

7. X-ray PEEK has good transmission performance, and does not produce artifacts formed by metal implants under X-ray and CT examination, which is convenient for patients in medical examination and other aspects.

(CFRTP-UD belt) production line characteristics:

1, process temperature: 400°C;

2, type of fiber produced: carbon fiber;

3, PEEK polyether ether ketone: carbon fiber = 50% : 50%;

4, can produce plastic raw material: PEEK;

5, production speed: 2-4 m/min;

6, production product thickness: 0.2-0.25mm,

7, production width: 600 mm