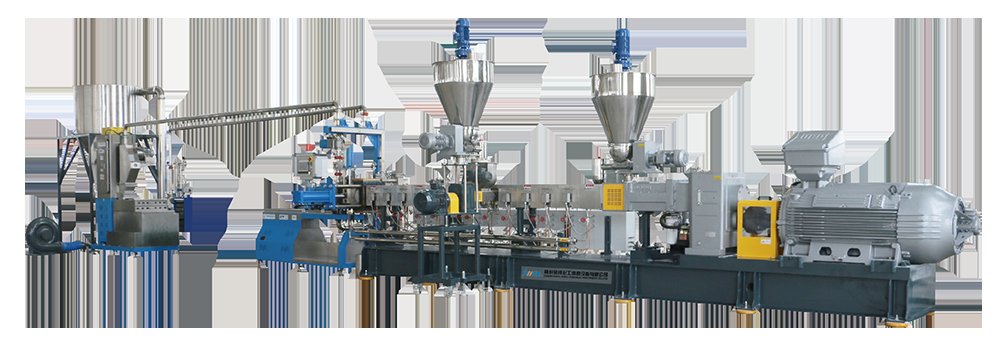

Complete set of granulation equipment with large yield and high filling

Filler masterbatch is composed of adding talc powder, calcium carbonate, kaolin, inorganic powder and plastic carrier, lubricant, through premixed or multi-way weightless feeding by twin screw granulation, the masterbatch is widely used in polyethylene, polypropylene, polyvinyl chloride, polyester, ABS, PS, EVA, pipe, wire, film, packaging belt, injection molding, extrusion and so on plastic products, With enhancement, increment, reduce cost, improve heat resistance, low carbon environmental protection. According to the material can be divided into: PP calcium carbonate filler masterbatch, PE calcium carbonate filler masterbatch, talc powder filler masterbatch, transparent filler masterbatch.

Product characteristics

Filler masterbatch is composed of adding talc powder, calcium carbonate, kaolin, inorganic powder and plastic carrier, lubricant, through premixed or multi-way weightless feeding by twin screw granulation, the masterbatch is widely used in polyethylene, polypropylene, polyvinyl chloride, polyester, ABS, PS, EVA, pipe, wire, film, packaging belt, injection molding, extrusion and other plastic products, With enhancement, increment, reduce cost, improve heat resistance, low carbon environmental protection. According to the material can be divided into: PP calcium carbonate filler masterbatch, PE calcium carbonate filler masterbatch, talc powder filler masterbatch, transparent filler masterbatch.