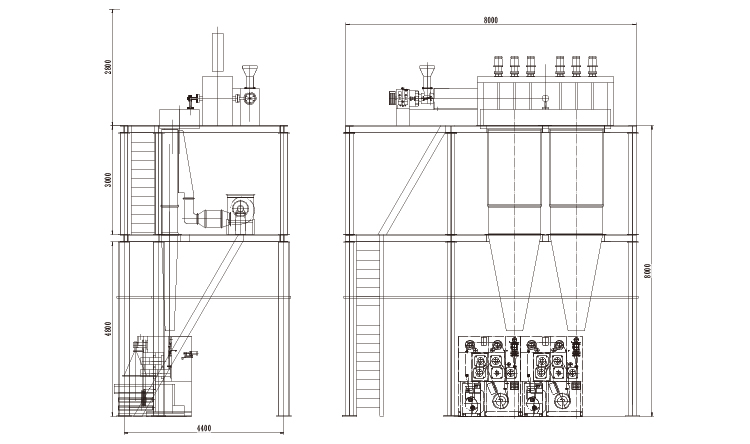

BCF carpet yarn spinning line

Product characteristics

Main features:

■1. Using PA6, PET and PP as raw materials, BCF yarn is produced by one step process of spinning, drawing and deformation. PP raw material can be added to the recovery material, reduce the cost. PET raw material can be 100% bottle tablets.

■2. Using the combination of spinning, drawing, winding and other modular equipment, can produce monochrome, three-color BCF carpet silk; The weight type color matching system is adopted to ensure the unity of the original silk color.

3. Adopt new screw, barrel, special process design, suitable for a variety of polymer production.

■4. Use specially designed puffed silk assembly, easy to replace, ensure the spinning melt distribution uniform, no dead Angle.

■5. Special rotary puffing device is used to improve the stability of rotary puffing BCF silk.

■6. Specially designed monomer suction system can discharge oligomers and lactam.

■7. The new nozzle type shape-shifting device, matching with optimized cooling drum, ensures excellent crimping.

■8. The induction heating roll is driven by synchronous motor, high frequency heating, imported temperature control transmitter, to ensure the uniform temperature of the hot roll.

■9. Automatic yarn switching winding head, constant yarn tension, high switching success rate, good cake forming.

Main technical parameters

Suitable spinning range: 600D-3600D;

Mechanical speed: 2800m/min

Bit distance: 1700mm

Number of heads per head: 2/3

Diameter of spinneret: 120mm/150mm

Component form :. Top or bottom

Cold beam cooling mode: side blowing

Diameter of hot roll: φ220mm

Expansion deformers: friction vane or non - disc deformers

Cooling drum: φ400mm, φ420mm

Winding head: automatic switch winding head